PRODUCTS

Silicon Carbide Heater

Qingdao Decent Group silicon carbide heating element is a rod-shaped non-metallic high-temperature heating element made of high-quality green silicon carbide as the main raw material, which is processed into a billet, high-temperature silicification, and recrystallized. Compared with metal electric heating elements, this element has the characteristics of high service temperature, oxidation resistance, corrosion resistance, long life, slight deformation, and convenient installation and maintenance. Therefore, it is widely used in a variety of high-temperature electric furnaces and other electric heating equipment in industries such as magnetic materials, powder metallurgy, ceramics, glass, metallurgy and machinery.

Silicon carbide heater for accurate and constant temperature

Qingdao Decent Group silicon carbide heater elements is a rod-shaped non-metallic high-temperature heating element made of high-quality green silicon carbide as the main raw material, which is processed into a billet, high-temperature silicification, and recrystallized. Compared with metal electric heating elements, this element has the characteristics of high service temperature, oxidation resistance, corrosion resistance, long life, slight deformation, and convenient installation and maintenance. Therefore, it is widely used in a variety of high-temperature electric furnaces and other electric heating equipment in industries such as magnetic materials, powder metallurgy, ceramics, glass, metallurgy, and machinery.

Silicon carbide heating elements are manufactured with a new cold-end process. In this process, the cold and hot ends have excellent resistance ratios. A silicon carbide element can be energy-efficient and last longer, while also preventing excessive temperatures at the cold end from damaging the furnace body.

Qingdao Decent Group Silicon Carbide Heater is a non-metallic electric heating element. It is made of high-purity hexagonal silicon carbide as the main raw material and recrystallized at 2200 ℃. The normal use temperature can reach 1450 ℃ and can be used continuously for more than 2000 hours. It is suitable for all kinds of Decent electric furnaces and Decent heating equipment.

Advantages of Silicon Carbide Heater

- High temperature and good chemical stability.

- Matching with an automatic power supply system, the temperature can be accurately constant.

- According to the actual needs of the production process, the temperature can be adjusted automatically.

- Easy to use, safe, and reliable.

Technical Parameters

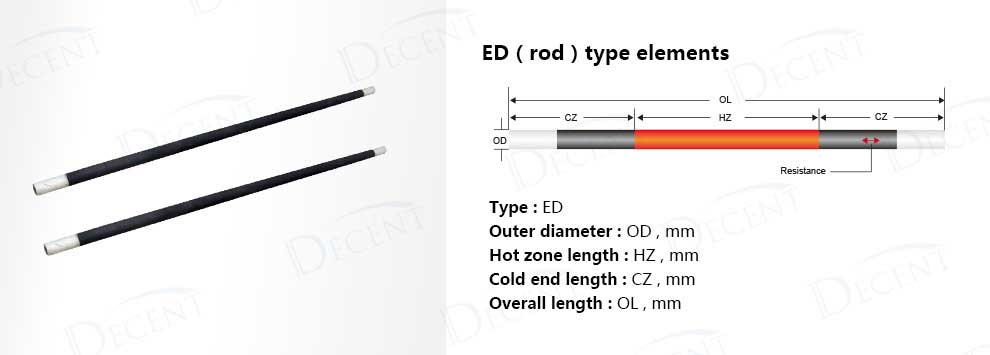

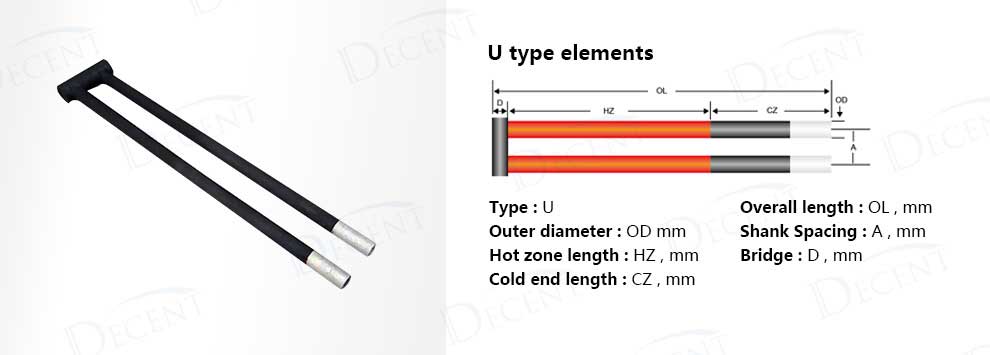

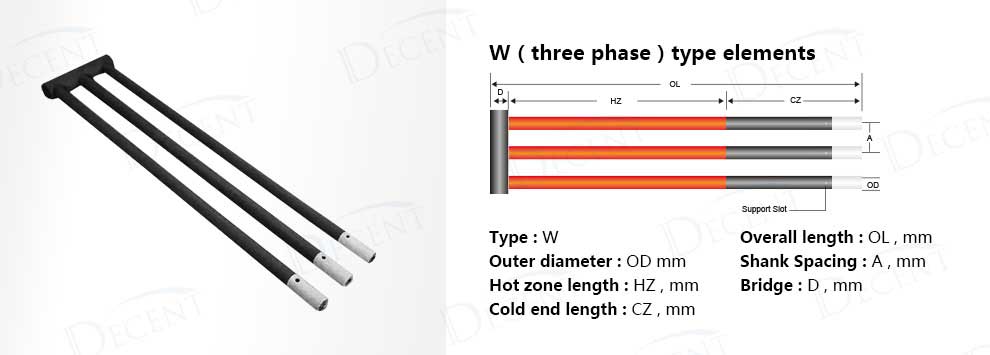

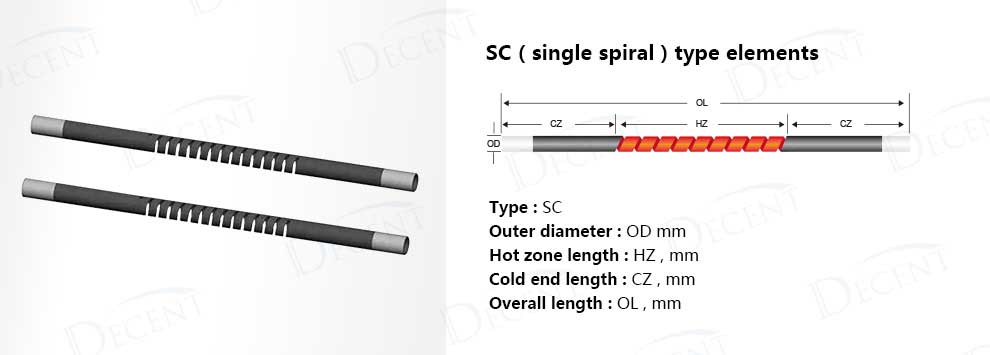

According to the diameter, it can be divided into two types: thick end and equal diameter.

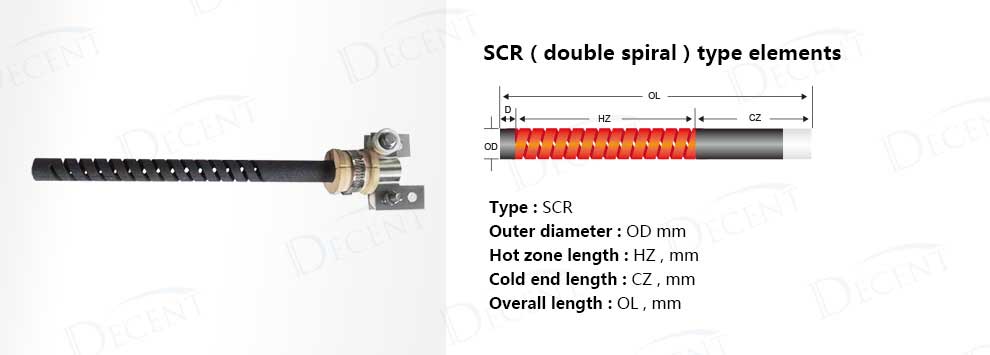

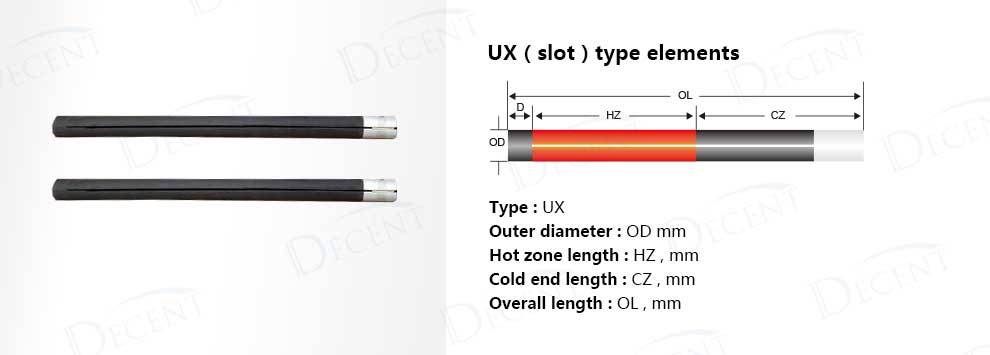

According to the functional shape, it can be divided into straight Elements, multi-heating section straight Elements, U-shaped Elements, W-shaped Elements, single and double thread Elements, groove Elements, gun-shaped Elements, door-shaped Elements, etc.

Component Texture

- hard and brittle

- resistant to rapid cooling and heating

- not easy to deform under high temperature

Decent Silicon carbide elements – physical properties

Density: 3.2g/cm3

Mohs hardness: 9.5

Specific heat: 0.17 kcal / kg · degree

Thermal conductivity: 20 kcal / m · h · D

Coefficient of linear expansion: 5 × 10-6(m/℃)

Decent Silicon carbide heater – chemical properties

The silicon carbide heater has good chemical stability and strong acid resistance. Under the condition of high temperatures, alkaline substances can corrode them.

When the silicon carbide heater is used above 1000 ℃ for a long time, it can interact with oxygen and water vapor as follows:

Sic+2O2→Sio2+CO2 ②Sic+4H2O=Sio2+4H2+CO2