PRODUCTS

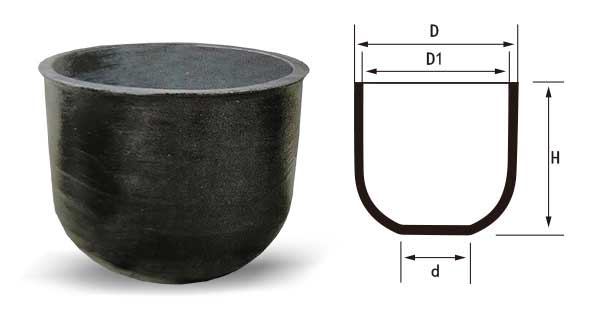

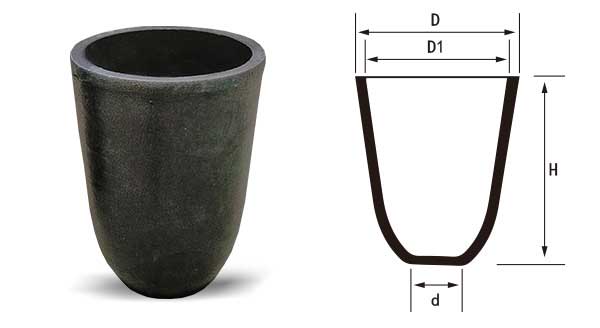

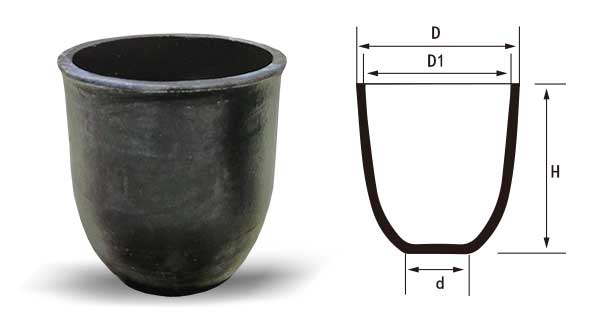

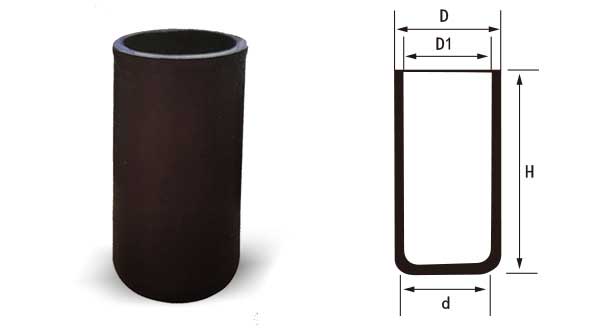

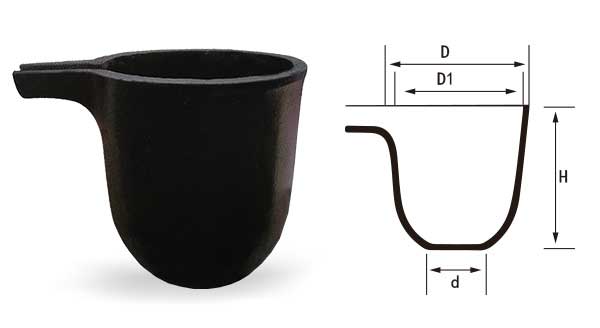

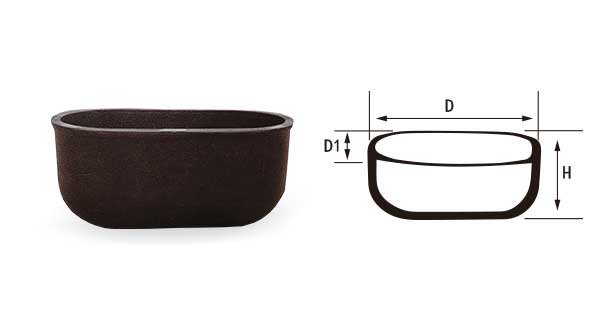

Silicon Carbide Graphite Crucible

Qingdao Decent Group has developed a new generation of high-quality silicon carbide graphite crucibles by using cutting-edge isostatic pressing crucible molding equipment, selecting the best refractory materials, and utilizing high-tech formulas. We supply silicon carbide graphite crucibles with features such as high density, high temperature resistance, quick heat transfer, acid and alkali corrosion resistance, high temperature strength, and high resistance to oxidation. In comparison to clay graphite crucibles, it has a three to five times longer service life.

Crafted with the best refractory materials and high-tech formulas

Qingdao Decent Group has developed a new generation of high-quality silicon carbide graphite crucibles by using cutting-edge isostatic pressing crucible molding equipment, selecting the best refractory materials, and utilizing high-tech formulas.

We supply silicon carbide graphite crucibles with features such as high density, high temperature resistance, quick heat transfer, acid and alkali corrosion resistance, high temperature strength, and high resistance to oxidation. In comparison to clay graphite crucibles, it has a three to five times longer service life.

Types of furnaces supported: resistance furnace, medium frequency electric furnace, electromagnetic induction furnace, biological particle furnace, gas furnace, coke furnace, oil furnace, gas generator, etc.

Application areas: melting gold, silver, copper, aluminum, tin, lead, zinc, and several non-ferrous metal alloys.

Advanced Features

• The high density of graphite crucible makes the crucible have the best thermal conductivity

• The graphite crucible has a special glaze layer and dense molding materials, which greatly improves the corrosion resistance of the product and prolongs its service life

• The graphite components in the graphite crucible are all natural graphite, which has very good thermal conductivity. After the graphite crucible is heated, it should not be placed on a cold metal table immediately to prevent it from cracking due to rapid cooling.

Technical Parameters

|  |  |

|  |  |

Maintenance and storage

Graphite crucibles should be protected from moisture. Moisture is the most fearsome enemy of graphite crucibles, which will negatively affect their quality. Using damp crucibles will result in cracks, bursts, falling sides, and even industrial accidents, leading to loss of molten metal. As a result, graphite crucibles must be protected from moisture when stored and used.

Graphite crucibles should be stored in a dry warehouse that is well ventilated and kept between 5°C and 25°C with a relative humidity of 50-60%. It is not recommended to store the crucible on brick soil or cement floor to avoid moisture. The bulk graphite crucibles should be placed on a wooden shelf, ideally 25 to 30 cm from the ground. For the whole package packed in wooden boxes, wicker baskets or straw bags, the stacks should be padded with sleepers and at least 20 cm from the ground. A layer of linoleum on the sleepers provides better moisture insulation. It is necessary to stack the stack for a period of time, and then dump the lower layer on top of the upper layer, ideally so that the upper and lower layers are laid next to each other. The stacking time interval should not be too long. Generally, stacking should be done once every two months. If the ground is not damp, the stacking can be stacked once every three months. In short, the good moisture-proof effect can only be achieved by frequent piling.